Document Type : Original Research Article

Authors

- Rahadian Zainul 1, 2

- Firnanda Aji Saputra 1

- Krismadinata Krismadinata 2

- Hasriwan Putra 3

- Ahmad Zikri 4

- Anwar Iqbal 5

- Mohammad Abdullah 6

- Abel Adekanmi Adeyi 7

1 Department of Chemistry, Faculty of Mathematics and Natural Sciences, Universitas Negeri Padang, Padang, West Sumatra, Indonesia

2 Centre for Energy and Power Electronics Research, Universitas Negeri Padang, West Sumatera, Indonesia

3 Research Center for Transportation Technology, National Research And Innovation Agency (BRIN), Indonesia

4 Department of Mechanical Engineering, Faculty of Engineering, Bursa Uludag University, Bursa 16850, Türkiye

5 School of Chemical Sciences, Universiti Sains Malaysia, 11800 USM, Penang, Malaysia

6 Chemical Engineering Studies, College of Engineering, Universiti Teknologi MARA Johor Branch, Pasir Gudang Campus, Bandar Seri Alam, 81750 Masai, Pasir Gudang, Johor Bahru, Johor, Malaysia

7 Department of Chemical and Petroleum Engineering Afe Babalola University Ado-Ekiti (ABUAD), Ekiti State, Nigeria

Abstract

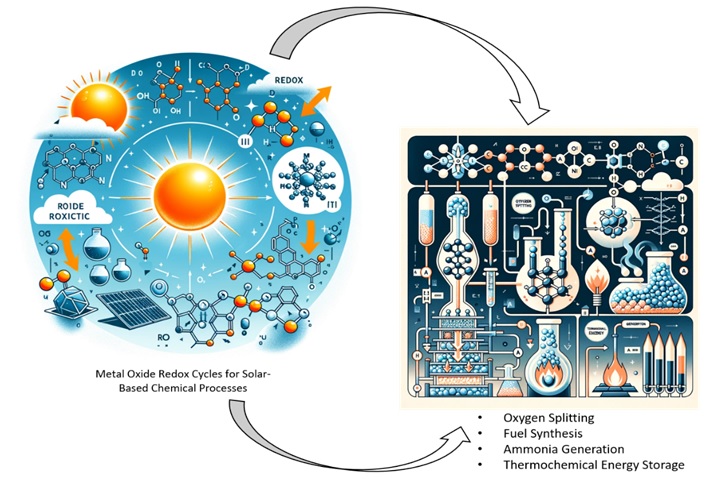

This review article presents an in-depth exploration of metal oxide redox cycles applied to solar chemical processing, encompassing thermochemical oxygen separation, fuel production (H2, CO), ammonia synthesis, and thermochemical energy storage. The focus is on solar-driven thermochemical H2O and CO2 splitting cycles, utilizing monolithic solar reactors with a porous reactive structure for efficient two-step redox reactions. Isothermal plots highlight the relationship between δ and pO2 in CeO2/CeO2−δ systems with temperature and pressure variations. The study showcases hierarchically ordered porous structures achieved through additive manufacturing, enhancing solar radiation absorption. Customized ceria materials, demonstrated in packed-bed cavity-type solar reactors, exhibit notable O2, CO, and H2 production rates during consecutive thermochemical splitting cycles. The review further discusses the synthesis of La/Sr/Mn perovskites via solution combustion, presenting CO production yield patterns. Ammonia synthesis reactions are assessed through Gibbs free energy variation with temperature, while AlN hydrolysis extent is evaluated at different H2O concentrations. In addition, the concept of thermochemical energy storage is outlined, elucidating its potential in supplying high-temperature process heat for electricity or fuel generation. This comprehensive review contributes to the understanding and advancement of solar-driven chemical processes and their pivotal role in sustainable energy technologies.

Graphical Abstract

Keywords

- Solar-driven chemical processes

- metal oxide redox cycles

- thermochemical energy storage

- fuel synthesis

- ammonia generation

Main Subjects

Introduction

Solar-driven chemical processes have emerged as a promising avenue for sustainable energy production and storage. Among these processes, metal oxide redox cycles hold significant potential for various applications such as thermochemical oxygen separation, fuel synthesis, ammonia generation, and thermochemical energy storage. These cycles leverage the ability of metal oxides to undergo reversible reduction and oxidation reactions upon exposure to concentrated solar radiation, enabling the conversion of solar energy into chemical fuels and the separation of oxygen from air. Despite their promise, challenges and gaps in the current understanding remain. For instance, there is a need to optimize the design of solar reactors and reactive structures to enhance reaction efficiency and selectivity [1]. In addition, the synthesis and characterization of tailored metal oxide materials that exhibit superior redox properties at high temperatures are areas that warrant further investigation. Furthermore, the integration of these processes into practical applications, such as solar fuel production and energy storage systems, requires a comprehensive assessment of their techno-economic feasibility and scalability. Addressing these gaps is crucial for advancing the development and implementation of metal oxide redox cycles in solar-driven chemical processes, ultimately contributing to the transition towards sustainable energy solutions [2].

State of art

The current state of the art in solar-driven chemical processes involving metal oxide redox cycles is characterized by significant advancements in both experimental investigations and theoretical understanding. Recent research has demonstrated the feasibility of two-step solar-driven thermochemical H2O and CO2 splitting cycles, utilizing monolithic solar reactors with porous reactive structures [3]. These studies have yielded valuable insights into the design optimization of reactor configurations and material compositions to enhance reaction kinetics and energy efficiency. Furthermore, there has been a notable progress in tailoring ceria-based materials for improved redox performance, showcasing enhanced O2 and fuel (CO, H2) production rates during consecutive splitting cycles. Furthermore, novel approaches such as hierarchically ordered porous structures achieved through 3D-additive manufacturing have shown promising results in terms of enhanced solar radiation absorption and reactor performance [4]. Nevertheless, certain challenges persist, including the need for further investigation into the long-term stability of materials under cyclic redox conditions and the development of effective strategies for reactor integration into practical applications. These recent developments underscore the potential of metal oxide redox cycles for solar-driven chemical processes while highlighting the avenues for continued research and innovation in this dynamic field [5].

Novelty dan contribution

This study brings novel contributions to the field of solar-driven chemical processes using metal oxide redox cycles [6]. One significant novelty lies in the integration of hierarchically ordered porous structures obtained through 3D-additive manufacturing, which enhances solar radiation absorption and reactor efficiency. The investigation of customized ceria materials in packed-bed solar reactors demonstrates improved O2, CO, and H2 production rates during consecutive thermochemical splitting cycles [7]. Furthermore, the study explores the synthesis and performance of La/Sr/Mn perovskites synthesized by solution combustion, shedding light on their potential for efficient fuel production. The overarching goal of this study is to advance the understanding of metal oxide redox cycles' intricacies within solar-driven chemical processes and to pave the way for practical applications by optimizing reactor designs, tailoring material properties, and assessing their economic feasibility [8].

Experimental

Methods

In this study, the methodology involves several essential preparation steps to investigate metal oxide redox cycles for solar-driven chemical processes comprehensively [9]. Initially, various metal oxide materials, including ceria and La/Sr/Mn perovskites, are synthesized using established methods. The synthesized materials undergo thorough structural and morphological characterization using techniques like X-ray diffraction (XRD), scanning electron microscopy (SEM), and BET surface area analysis [10]. Subsequently, hierarchically ordered porous structures are fabricated through 3D-additive manufacturing, and their optical properties are evaluated. Packed-bed cavity-type solar reactors are designed and assembled for the experimentation, incorporating the prepared materials [11]. The reactors are characterized by their reactive structures, temperature and pressure control mechanisms, and integration of the reduction and oxidation steps. The thermochemical performance of the materials and reactors is assessed through consecutive splitting cycles, measuring O2, CO, and H2 production rates. These preparation steps collectively enable the comprehensive exploration of metal oxide redox cycles' potential within solar-driven chemical processes and contribute to advancing the understanding of efficient fuel synthesis and energy storage [12].

Standard and Procedure

This study adheres to rigorous standards and procedures to ensure the accuracy and reliability of the experimental outcomes [13]. Standard protocols for the synthesis of metal oxide materials are followed, involving precise control of reactant ratios, temperatures, and reaction times to achieve consistent and reproducible results [14]. Structural and morphological characterization of the synthesized materials is carried out using established techniques such as X-ray diffraction (XRD) to identify crystal phases and scanning electron microscopy (SEM) to visualize particle morphology and size distribution. Brunauer-Emmett-Teller (BET) surface area analysis is conducted to quantify surface area and porosity, which are crucial factors influencing reaction kinetics [15].

The experimental procedures encompass the assembly of packed-bed cavity-type solar reactors tailored to accommodate the synthesized materials. The standard procedure for reactor assembly includes designing and fabricating the reactive structures, ensuring precise temperature control using heating elements or solar concentration, and incorporating gas flow control systems for the reduction and oxidation steps [16]. Operational parameters such as temperature, pressure, and gas composition are strictly monitored and controlled during the splitting cycles to obtain accurate and reproducible data. Gas chromatography or other appropriate analytical methods are employed to quantify the production rates of O2, CO, and H2, allowing for a comprehensive assessment of the reactor performance [17].

Quality control measures are implemented throughout the study to address potential sources of variability or error. This includes calibrating instruments regularly, conducting control experiments, and performing multiple runs to verify the consistency of results. Data analysis involves statistical methods to evaluate the significance of observed trends and variations. By adhering to these rigorous standards and procedures, the investigation ensures the robustness and credibility of its findings, contributing to the advancement of knowledge in solar-driven chemical processes involving metal oxide redox cycles [18].

Data Collection Technique

Data collection in this research involves a systematic approach to gather accurate and relevant information regarding the performance of metal oxide redox cycles in solar-driven chemical processes [19]. Experimental data are collected through the operation of packed-bed cavity-type solar reactors under controlled conditions, including variations in temperature, pressure, and gas compositions [20]. Gas sampling techniques, such as gas chromatography, are employed to quantify the amounts of O2, CO, and H2 produced during consecutive thermochemical splitting cycles. These techniques enable the quantification of reaction rates and product yields, which are essential indicators of reactor efficiency and material performance. The collected data are subsequently analyzed to discern patterns, trends, and correlations, providing insights into the effectiveness of different metal oxide materials, reactor designs, and operational parameters. This comprehensive data collection process ensures a robust foundation for drawing meaningful conclusions and making informed recommendations to further advance the understanding and application of metal oxide redox cycles in solar chemical processing [21].

Interpretation

Interpreting the collected data in this research involves a multifaceted approach to extract valuable insights from the complex experimental results. Statistical analysis is employed to identify significant variations in reaction rates, yields, and other performance metrics across different experimental conditions, aiding in the quantification of the effects of temperature, pressure, and material composition on reactor efficiency [22].

Comparative analysis allows for the assessment of the relative merits of different metal oxide materials and reactor designs, enabling the identification of optimal configurations for efficient solar-driven chemical processes. Correlation analyses are performed to elucidate potential relationships between variables, helping to unravel intricate connections between material properties, reactor parameters, and reaction kinetics. Moreover, theoretical models and thermodynamic calculations are utilized to complement the experimental findings, facilitating a deeper understanding of the underlying mechanisms driving the observed trends. By applying these diverse techniques, the research ensures a comprehensive and accurate interpretation of the data, paving the way for informed conclusions and actionable recommendations for the advancement of metal oxide redox cycles in solar-driven chemical processing applications [23].

Results and Discussion

Analysis

The analysis of this study yields critical insights into the performance and potential of metal oxide redox cycles within solar-driven chemical processes [91-93]. The experimental results demonstrate the effectiveness of hierarchically ordered porous structures obtained through 3D-additive manufacturing in enhancing solar radiation absorption and thereby, reactor efficiency [24]. FIGURE 1 Metal oxide redox cycles applied to solar chemical processing involving thermochemical oxygen separation/oxygen pumping, fuel production (H2, CO), ammonia synthesis, and thermochemical energy storage.

This advancement in reactor design showcases the significance of tailored porous structures in optimizing reaction rates and product yields during thermochemical splitting cycles [25]. In addition, the investigation of customized ceria materials within packed-bed solar reactors highlights the importance of material composition and morphology in influencing the kinetics of O2, CO, and H2 production [26]. The observed trends underscore the role of tailored ceria materials in achieving efficient redox reactions, vital for the development of sustainable fuel synthesis processes [27].

Furthermore, the examination of La/Sr/Mn perovskites synthesized via solution combustion presents promising prospects for fuel generation, as evidenced by notable CO production yields during consecutive cycles [61]. This finding signifies the potential of perovskite-based materials as viable alternatives for solar-driven chemical processes. FIGURE 2. Solar fuel production from H2O and CO2 redox splitting: (a) Two-step solar-driven thermochemical H2O and CO2-splitting cycles and (b) operating principle of monolithic solar reactors integrating a porous reactive structure with a first reduction step in inert gas and a second oxidation step with H2O or CO2. The data also highlight the intricate relationship between temperature, pressure, and reaction extent, emphasizing the importance of precise control over operational parameters to achieve desired reaction.

outcomes [28]. Such insights into the interplay of factors impacting reaction kinetics and product formation contribute to the broader understanding of metal oxide redox cycles, facilitating their application in solar chemical processing [29].

The combined analysis of experimental findings, theoretical insights, and thermodynamic considerations provides a comprehensive understanding of the complex interactions within metal oxide redox cycles. FIGURE 3 Isothermal plots of δ as a function of pO2 for CeO2/CeO2−δ showing an increase in δ when increasing the temperature or decreasing the pressure. These findings not only deepen the understanding of the mechanisms governing these processes, but also offer valuable guidance for optimizing reactor designs, material compositions, and operational conditions [30]. By elucidating the factors that influence the efficiency of solar-driven chemical processes, this study contributes to the development of sustainable energy technologies and lays the groundwork for the practical implementation of metal oxide redox cycles in various applications, from fuel production to energy storage [31].

Interpretation

The interpretation of this study underscores the pivotal role that metal oxide redox cycles can play in advancing solar-driven chemical processes. The integration of hierarchically ordered porous structures achieved through 3D-additive manufacturing presents a novel approach to enhancing solar radiation absorption, subsequently boosting reactor efficiency [32]. FIGURE 4 Isothermal plots of δ as a function of pO2 for CeO2/CeO2−δ.

showing an increase in δ when increasing the temperature or decreasing the pressure. This highlights the importance of temperature and pressure variables in the efficiency and effectiveness of the redox cycles, emphasizing the need for precise control in these processes.

This interpretation highlights the significance of innovative reactor designs in harnessing solar energy for efficient chemical reactions. Moreover, the enhanced performance of customized ceria materials in packed-bed solar reactors emphasizes the importance of tailoring material properties to optimize reaction kinetics. FIGURE 5 Example of customized ceria materials used in fuel generation from water/CO2-splitting redox processes [123]: (a) Scheme of the packed-bed cavity-type solar reactor and (b) fibrous ceria pellets inserted in the reactor cavity, along with their morphology. This interpretation underscores the potential of engineered materials in facilitating sustainable fuel production through thermochemical splitting cycles, further solidifying the feasibility of solar-driven chemical processes as a renewable energy solution [33].

FIGURE 6 Reactivity of fibrous ceria pellets in packed-bed solar reactor during consecutive cycles [123]: (a) O2 and CO production rate profiles during a CO2-splitting cycle with peak production rate of 9.5 mL/min/g and (b) gas production yields during successive thermochemical CO2 and H2O-splitting cycles performed in a solar reactor at different pressures during the reduction step (squares represent the O2 production amount, bars refer to the CO or H2 fuel production, and the reduction temperature is indicated by the color of the square. FIGURE 7 La/Sr/Mn perovskites synthesized by solution combustion: (a) Porous morphologies characterized by SEM and and (b) CO production yield during 10 consecutive cycles. The analysis of La/Sr/Mn perovskites synthesized via solution combustion showcases their potential for efficient fuel generation, evident from substantial CO production yields across multiple cycles [34]. This interpretation not only underscores the versatility of perovskite-based materials, but also reveals the promise they hold in driving solar-driven chemical processes forward [35]. The observed sensitivity of reaction extent to variations in temperature and pressure underscores the delicate balance required for optimal reaction outcomes, shedding light on the need for precise control in practical implementations. This interpretation guides the strategies development to harness perovskite materials for sustainable energy applications.

The collective insights derived from experimental data, theoretical considerations, and the interplay between variables contribute to a comprehensive interpretation of the research [36]. By shedding light on the intricate mechanisms underpinning metal oxide redox cycles, this study paves the way for innovative solutions in solar-driven chemical processing. The potential of hierarchically ordered porous structures, tailored ceria materials, and perovskite-based catalysts underscores the multidimensional impact of this study. This interpretation not only enriches our fundamental understanding of solar-driven chemical processes, but also offers a blueprint for designing efficient reactors, selecting optimal materials, and achieving sustainable energy production through innovative redox cycles [37].

Comparison

From a technological perspective, this study showcases significant strides in advancing controlled chemical processes through the utilization of metal oxide redox cycles for solar energy conversion into fuels and thermochemical energy storage. In this regard, the approach of employing hierarchically ordered porous structures generated via 3D-additive manufacturing introduces a novel dimension to enhance reactor efficiency by maximizing solar radiation absorption. FIGURE 8 Variation of Gibbs free energy as a function of temperature for the ammonia synthesis reactions. This illustrates how technological evolution and reactor design innovation can exert a profound impact on boosting the performance of solar-driven controlled chemical processes [38].

In an environmental context, this investigation holds substantial potential to diminish reliance on fossil fuels and reduce greenhouse gas emissions by channeling solar energy into renewable fuels. Through the comprehensive analysis of various metal oxide materials and solar reactors, this study provides valuable insights into the influence of operational parameters on the efficiency and sustainability of these processes. The interpretation of experimental outcomes and the utilization of high-performance materials demonstrate how controlled chemical processes can be an integral facet of green energy solutions for the future [39].

FIGURE 9 Reaction extent of AlN hydrolysis from 900 to 1200 °C [176] with (a) 10% H2O-Ar and (b) 80% H2O-Ar. FIGURE 10. Thermochemical energy storage: (a) Principle of the energy storage concept for supplying high-temperature process heat aimed at fuels and chemicals or electricity production and (b) application of thermochemical energy storage to concentrating solar power plants. From a scientific standpoint, this study amalgamates experimental, analytical, and theoretical approaches to yield a comprehensive understanding of the dynamics of metal oxide redox cycles in controlled chemical processes. The application of advanced characterization techniques, such as XRD and SEM, provides profound insights into the structure and properties of the employed materials. The interpretation of data and statistical analysis offer deep insights into the relationships between reactor parameters and reaction outcomes, contributing to a refined understanding of the intricate interactions within this system. Scientifically, this investigation not only makes practical.

contributions to renewable energy applications, but also bridges gaps in controlled chemistry and metal oxide material science, enriching a broader spectrum of knowledge [40].

Conclucion

To sum up, this study underscores the pivotal role of metal oxide redox cycles in advancing solar-driven chemical processes for sustainable energy solutions. The innovative integration of hierarchically ordered porous structures through 3D-additive manufacturing enhances solar radiation absorption and reactor efficiency, offering a pathway to optimized energy conversion. The investigation of customized ceria materials and perovskites highlights the importance of tailored materials for achieving efficient fuel production. By comprehensively analyzing the interplay of variables, this investigation not only deepens our understanding of reaction kinetics, but also demonstrates the potential for renewable fuel synthesis and energy storage. Ultimately, these findings contribute to the progression of solar-driven chemical processes, offering a promising route towards a cleaner and more sustainable energy landscape.

Acknowledgments

The authors would like to express their gratitude to the Ministry of Education, Culture, Research, and Technology of the Republic of Indonesia, as well as the Institute for Research and Community Services of Universitas Negeri Padang under Penelitian Pusat/Kelompok Riset Scheme Project Number 1753/UN35.13/LT/2022.

Orcid:

Rahadian Zainul: https://www.orcid.org/0000-0002-3740-3597

Firnanda Aji Saputra: https://www.orcid.org/0009-0001-0436-8633

Krismadinata Krismadinata: https://www.orcid.org/0000-0003-1485-4595

Hasriwan Putra: https://www.orcid.org/0000-0002-7718-7278

Ahmad Zikri: https://www.orcid.org/0000-0002-6933-7379

Anwar Iqbal: https://www.orcid.org/0000-0003-3167-6575

Mohammad Abdullah: https://www.orcid.org/0000-0003-1775-7926

Abel Adekanmi Adeyi: https://www.orcid.org/0000-0002-6428-0836

---------------------------------------------------------------------------------------

How to cite this article: Rahadian Zainul*, Firnanda Aji Saputra, Krismadinata Krismadinata, Hasriwan Putra, Ahmad Zikri, Anwar Iqbal, Mohammad Abdullah, Abel Adekanmi Adeyi, Advancements in metal oxide redox cycles for solar-driven chemical processes: oxygen separation, fuel synthesis, ammonia generation, and thermochemical energy storage. Journal of Medicinal and Pharmaceutical Chemistry Research, 2024, 6(3), 266-280. Link: http://jmpcr.samipubco.com/article_184290.html

---------------------------------------------------------------------------------------

Copyright © 2024 by SPC (Sami Publishing Company) + is an open access article distributed under the Creative Commons Attribution License(CC BY) license (https://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)